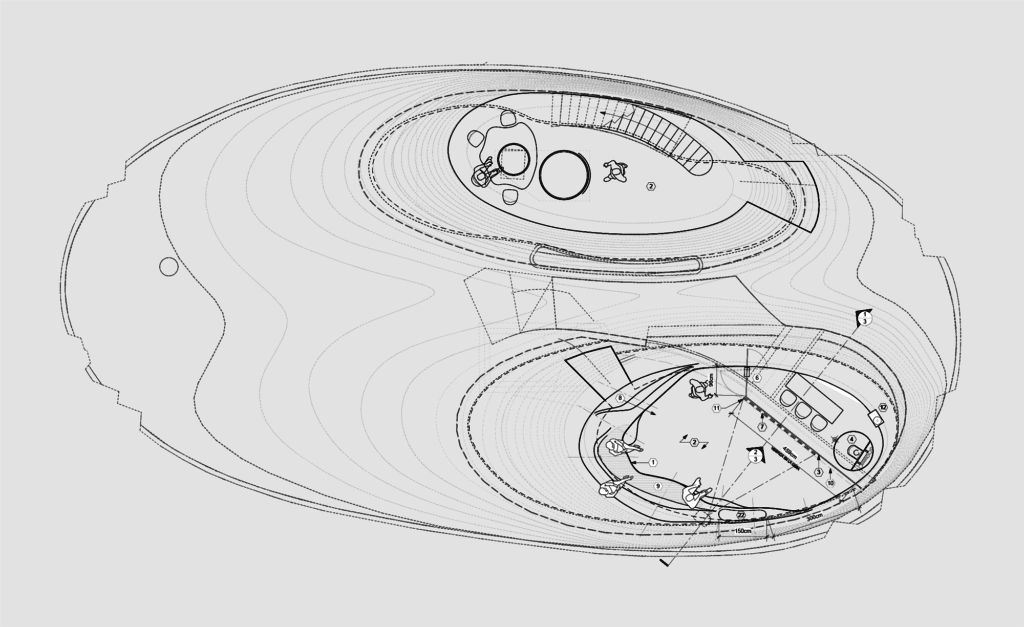

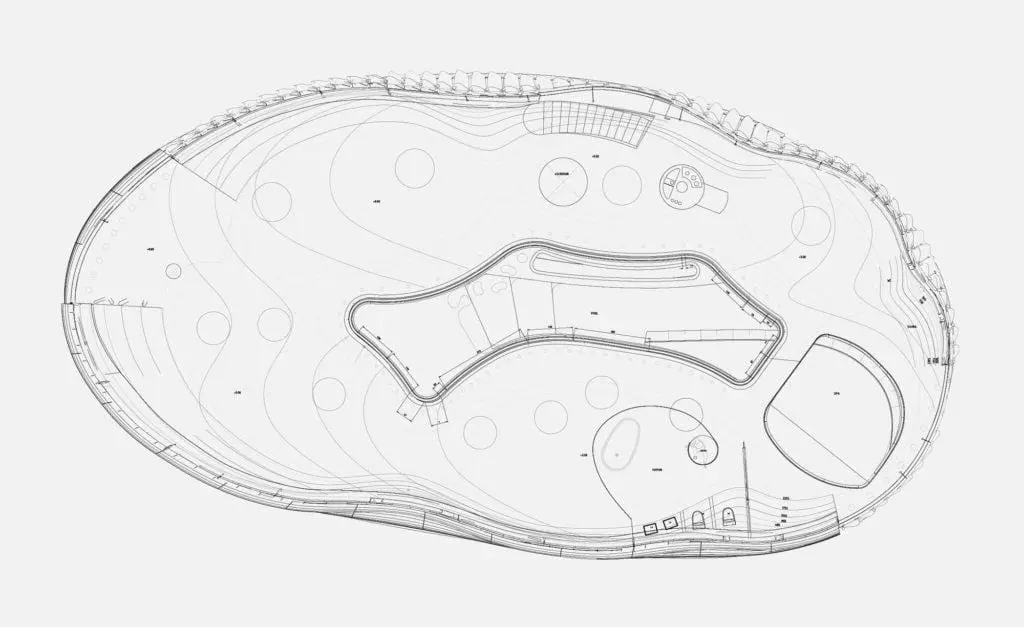

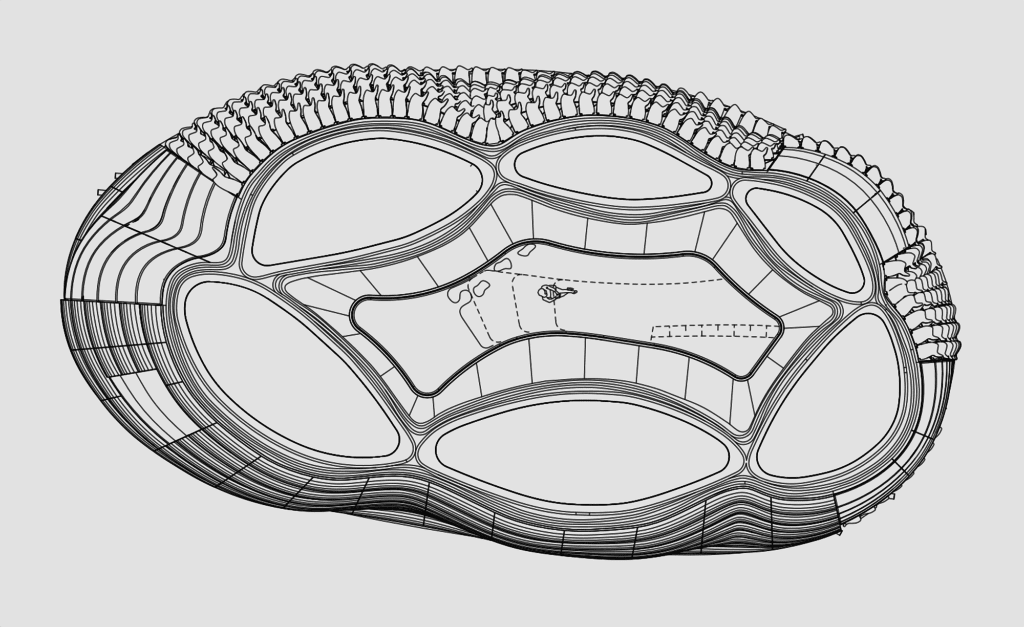

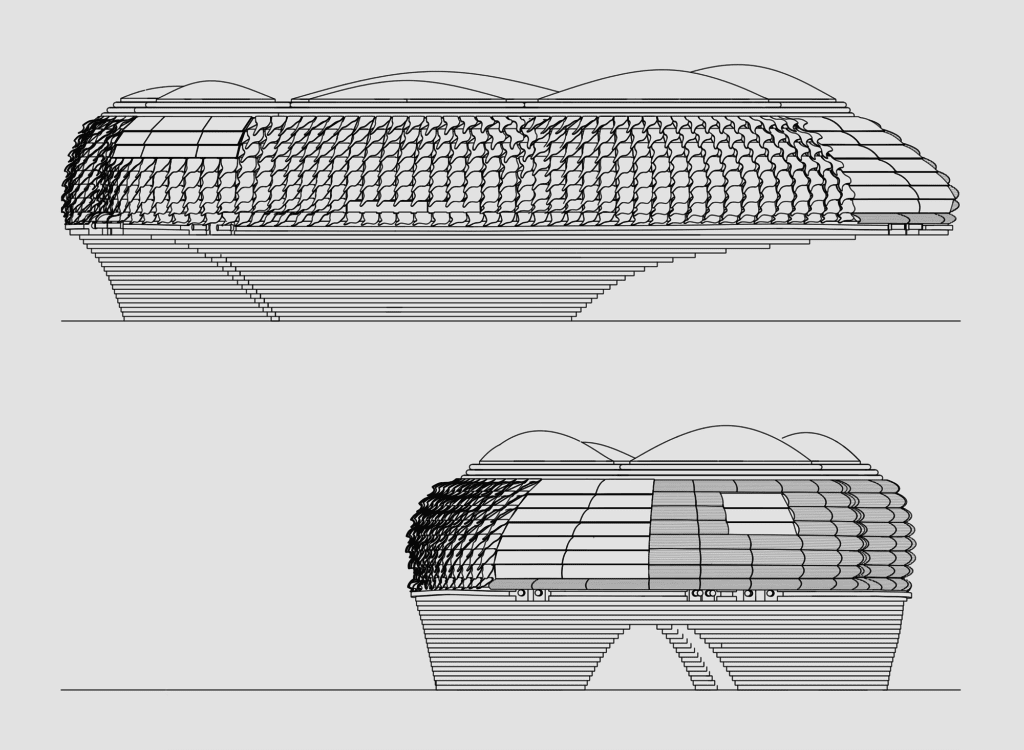

In villa Nurbs, located in Empuriabrava, the words project and process merge and complement each other. At the same time, it is a research project. Construction does not follow the sequence of conceptual design, basic design, detailed design and construction. Design and construction often go in parallel. On the one hand, this allows us to design in real scale, 1:1, see things get built, check the quality of materials and make decisions that respond to certain qualities which, following a traditional process, wouldn’t be percieved, or wouldn’t be percieved on time. On the other hand it allows us to use new materials and techniques that are being developed as the work progresses. That’s why materials that are not yet in the market are used in this project.

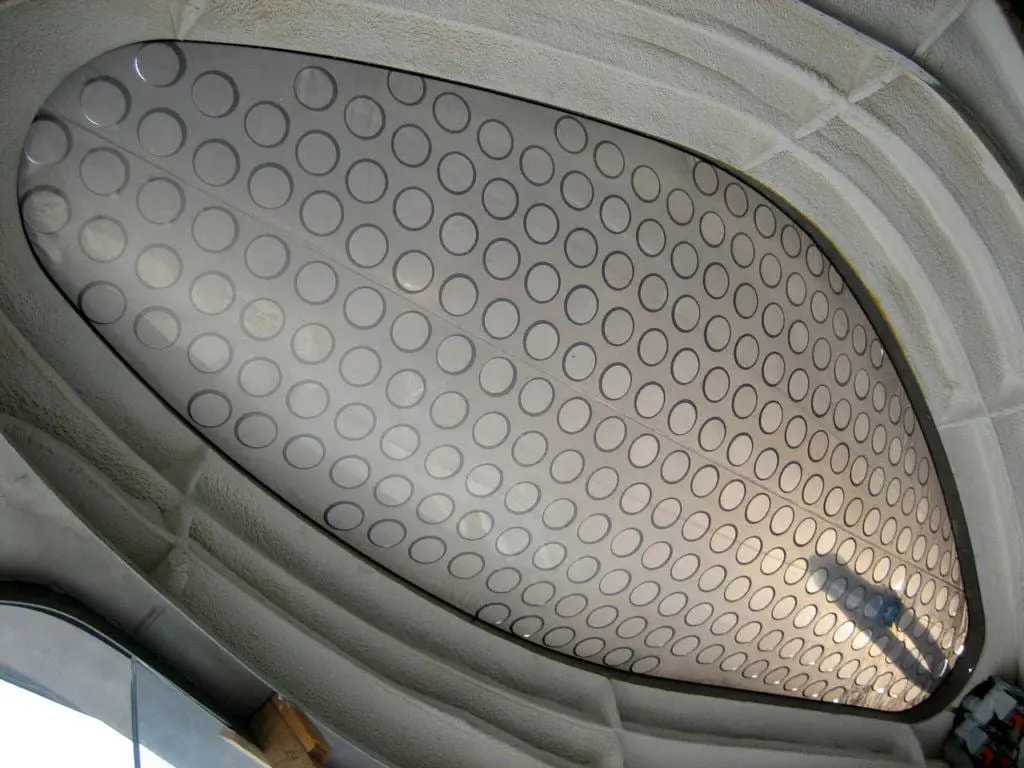

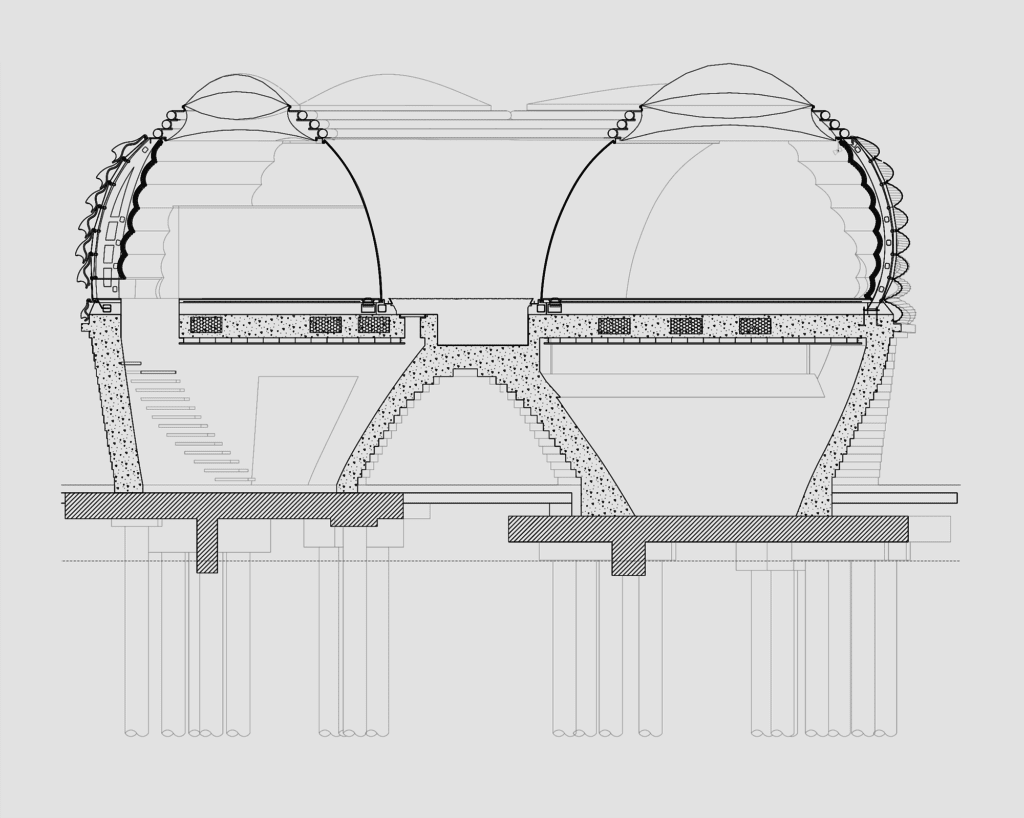

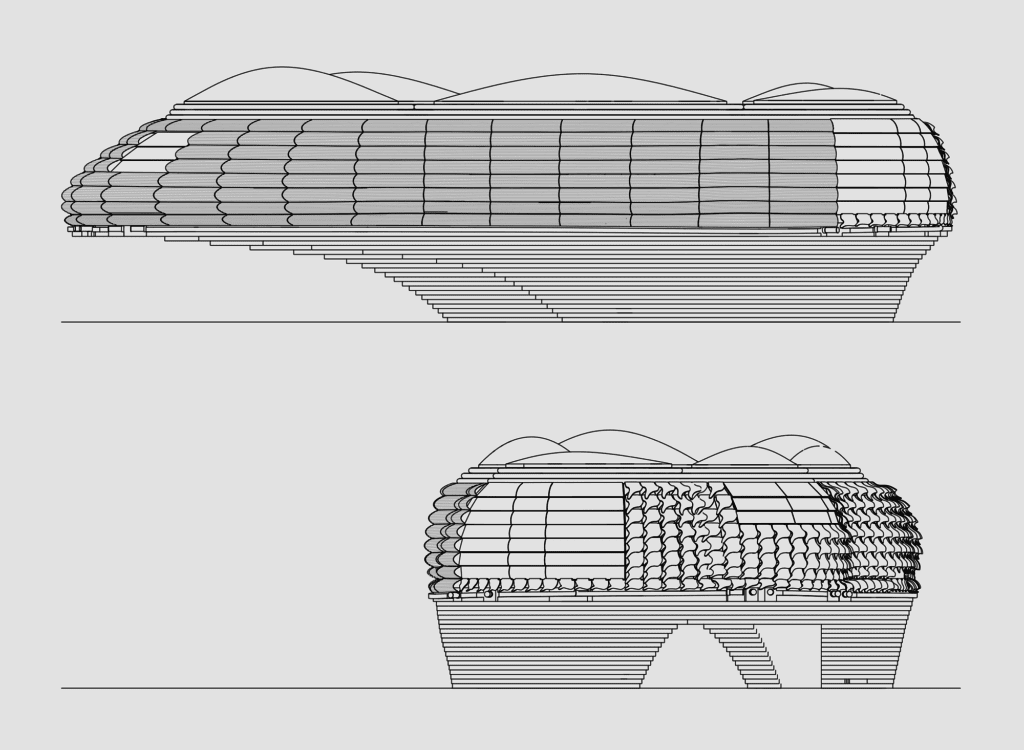

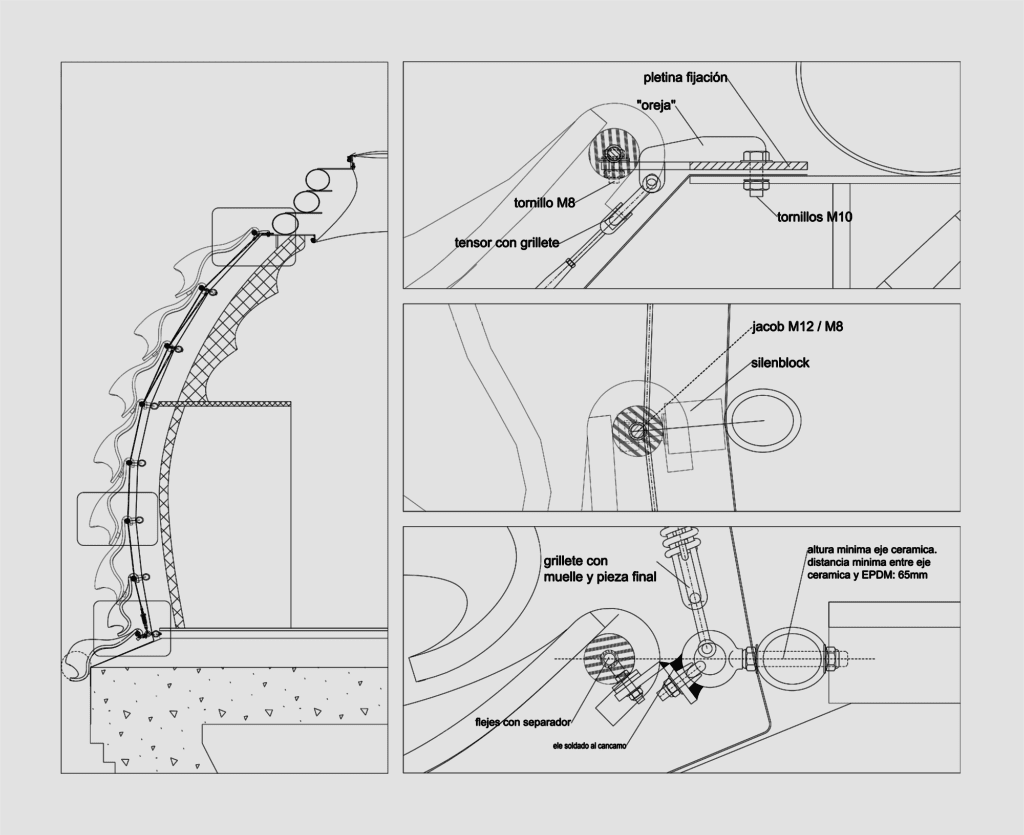

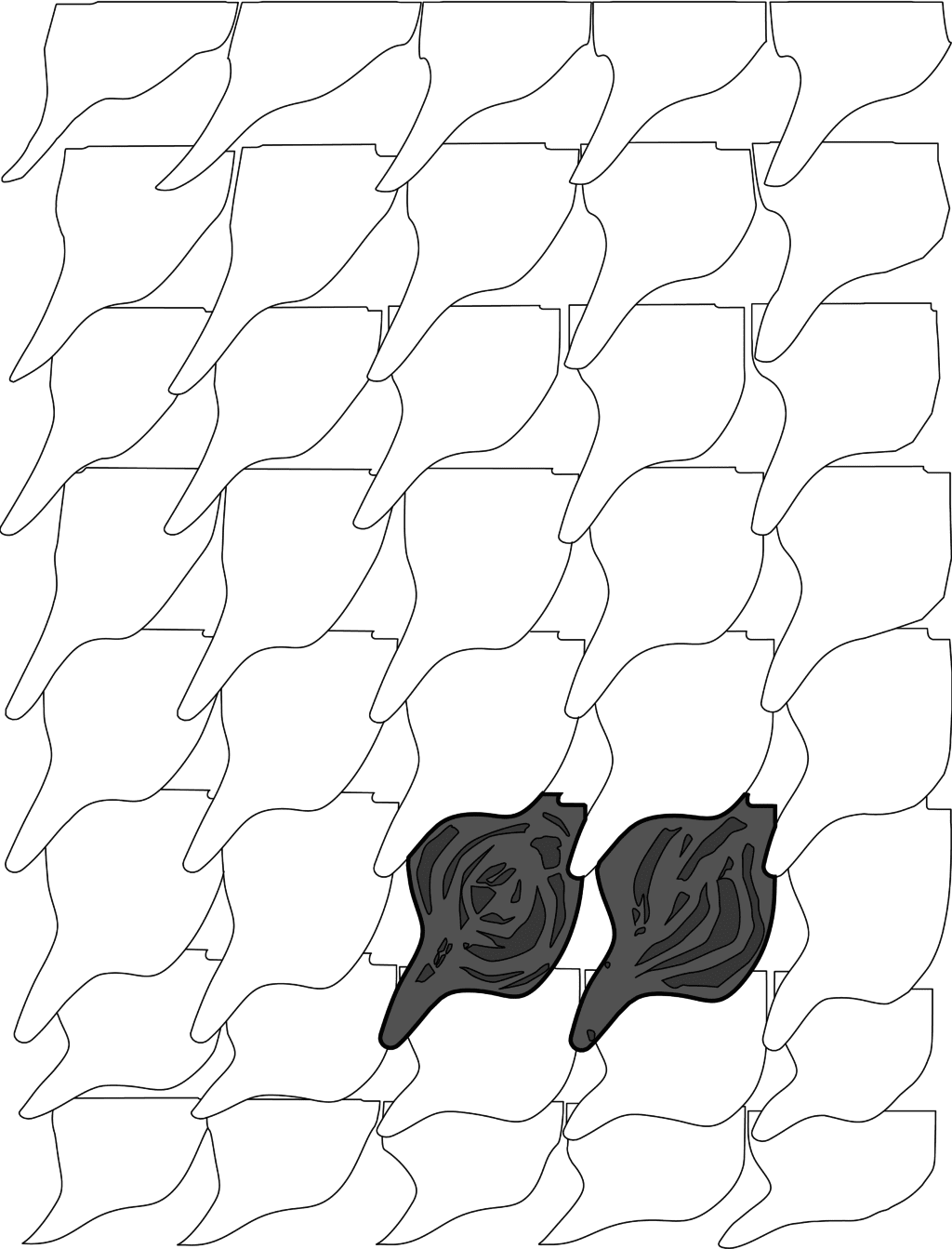

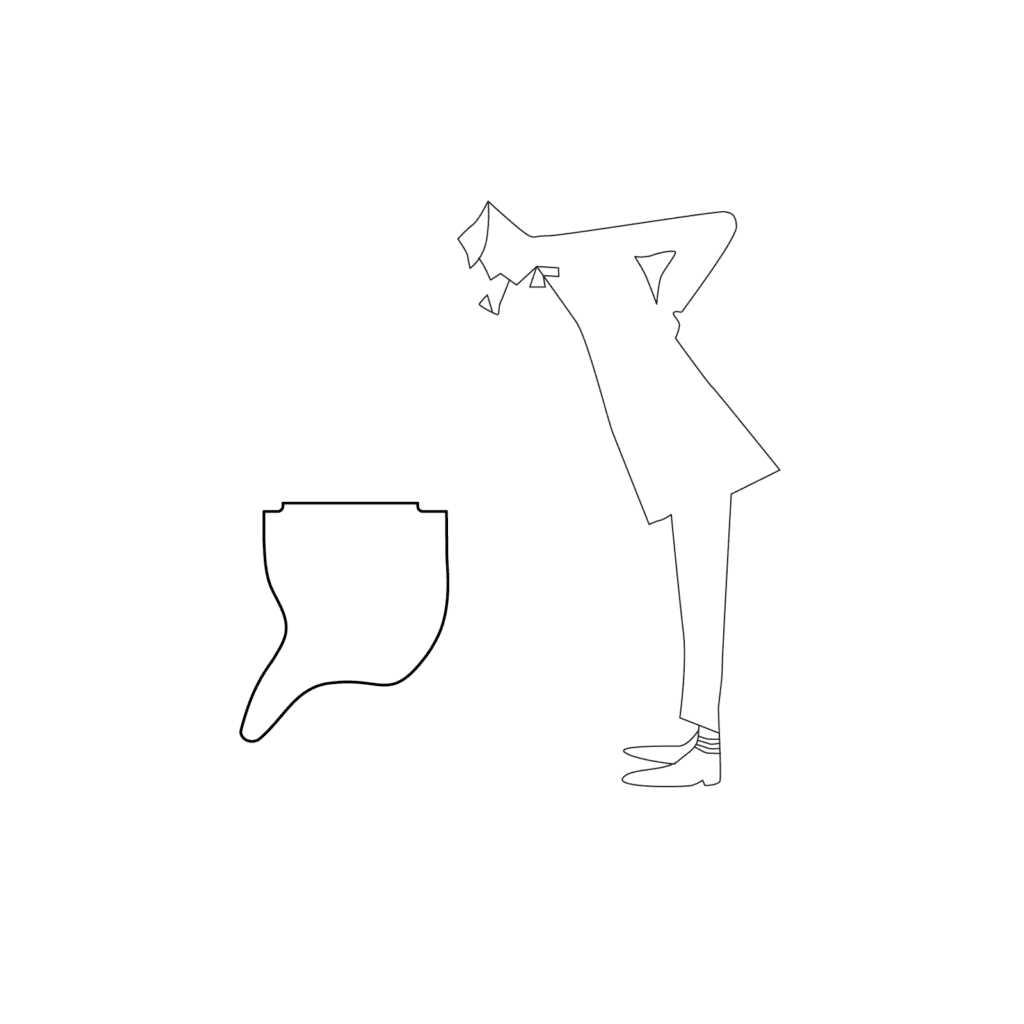

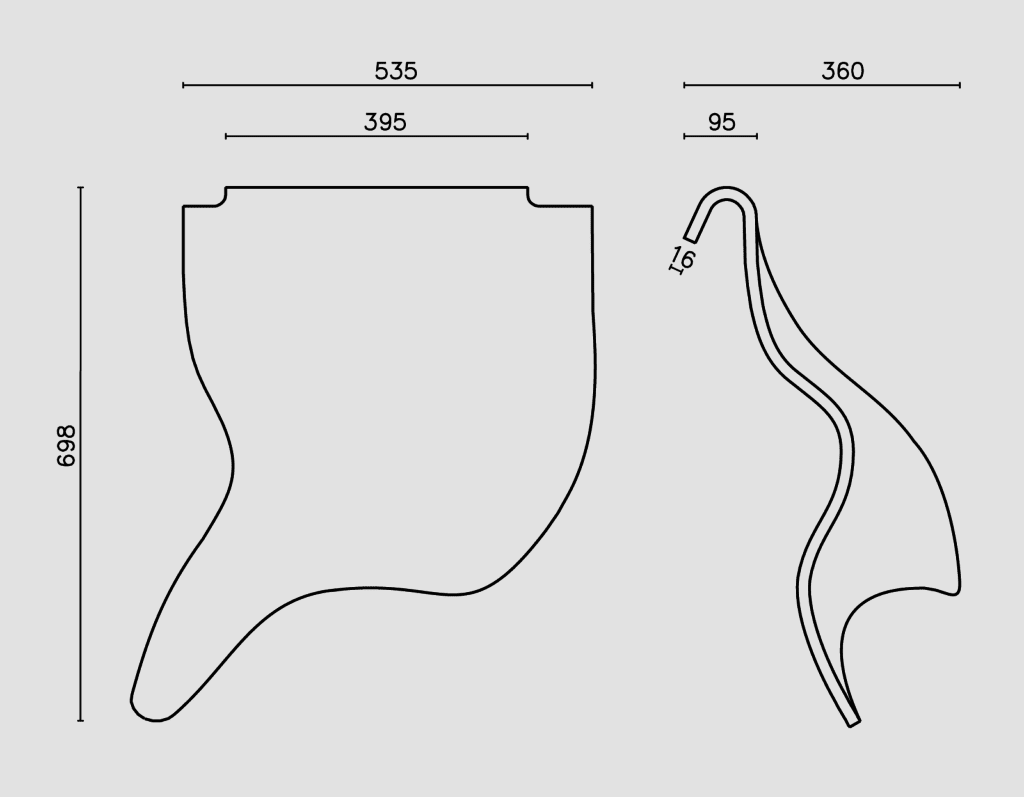

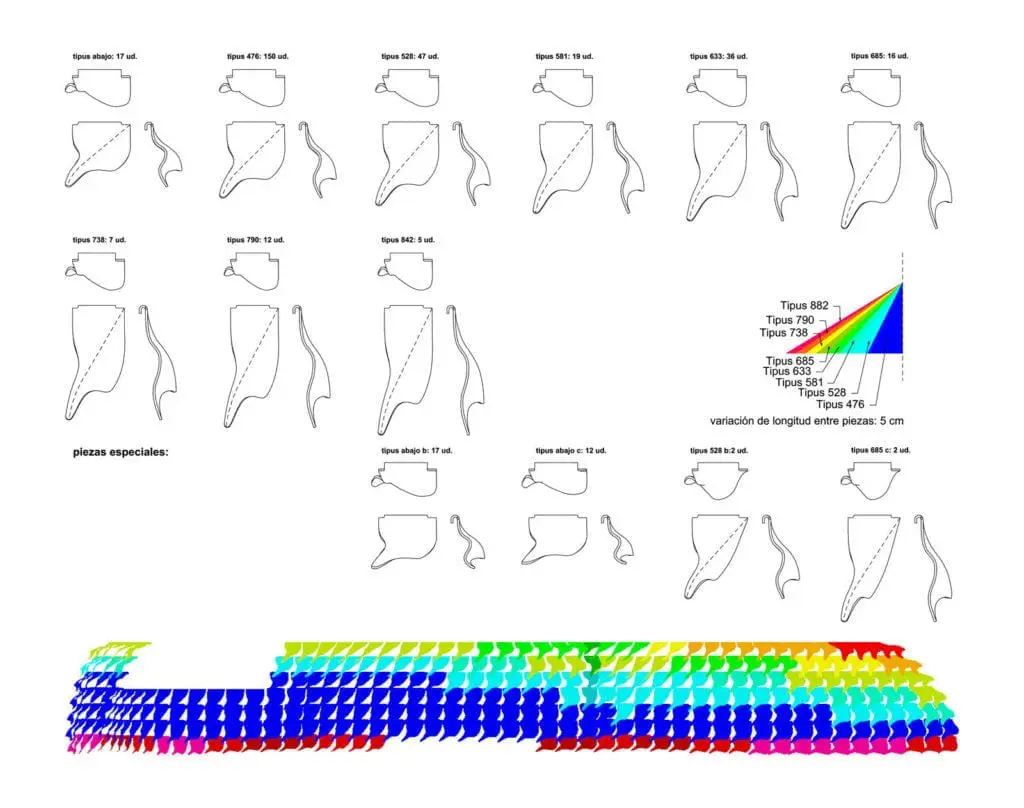

The construction is carried out through CAD-CAM: Cloud 9 computer-aided design is directly connected to the computer-aided manufacturing, applied by the different collaborators of the project. This process not only allows us to build things that were impossible before, but also is a new way to manage and communicate with the suppliers and engineers involved. There is only one 3D model of the project. From this model we get all the information necessary for each individual discipline. It is a way of direct communication. There isn’t a general builder in between. No information or precision is lost on the way: The laser-cut piece is a translation of the drawing into reality. However this production process is not standardized, and not all disciplines are connected to digital media. That is why, with each industrialist, artist or engineer collaborating, a new way to communicate has to be invented. Although the ceramic element can be understood as a unit, its study as an integral part in a whole has had to consider its repetition throughout the surface of the facade. Only in this way it has been possible to perceive its behavior. The main points considered for this study have been sun, wind and rain protection as well as the cooling of the facade. The result allows this skin to work as a set of leaves that protect the building from sun radiation, rain (channeling it from piece to piece by gravity) and the strong Tramontana wind coming from the mountains (but opening at the same time to the sea breeze).